These are very conservative values, to keep the bit tracking where it should go, and not stressing the bit so that it breaks.ĢMNS-Through.drl_mill_slot_0.6mmCutter_cnc.nc nc file used for isolation milling specifies the cutting depth at 0.15 mm, the Z feed rate at 30 mm/minute, and the X-Y feed rate at 60 mm/minute. A 0.1mm diameter tip, 20 degree V-bit was used for this, and prior to this operation, was installed in the spindle for creating the Height Map. The first operation was for isolation milling. Using the files linked in the introduction, the board was made as follows (In numerical order of 1 - 4) Without have the Height Map information to compensate for those variations, all of the milling operations will be less than optimal and may result in an unusable PCB. The Height Map contains a mapping of the height variation of both the underlying spoil board and the PCB substrate itself.

It is worth mentioning that the most important operation in producing a prototype PCB on a SainSmart CNC running Candle, is to create a Heightmap at the beginning of the process. Using a vacuum between operations is suggested, it clears the way for the next operation.įinally, the actual production of the PCB was done on my CNC running the Candle control program. Typically, on the order of 8000 to 9000 RPM. The spindle is running at maximum speed of 1000, whatever that is on your CNC machine. It holds the PCB blank securely, and additional single sided tape can be added around the perimeter of the PCB blank if in doubt that the double sided tape will do the job just make sure that it is outside the work area and height map of your project. The PCB material is held to the spoil board by using double sided tape, quite similar to carpet tape. nc files were created, one to do the isolation milling, one to mill the 0.6 mm slots to allow the PCB to fit over the motor power tabs, one to mill the large hole in the center of the PCB, so that it fits over the motor upper bearing housing, and a forth file that does a circular cut around the perimeter of the PCB, and mills the cooling slots that correspond to those on the motor.

#Diptrace pcb for cnc software#

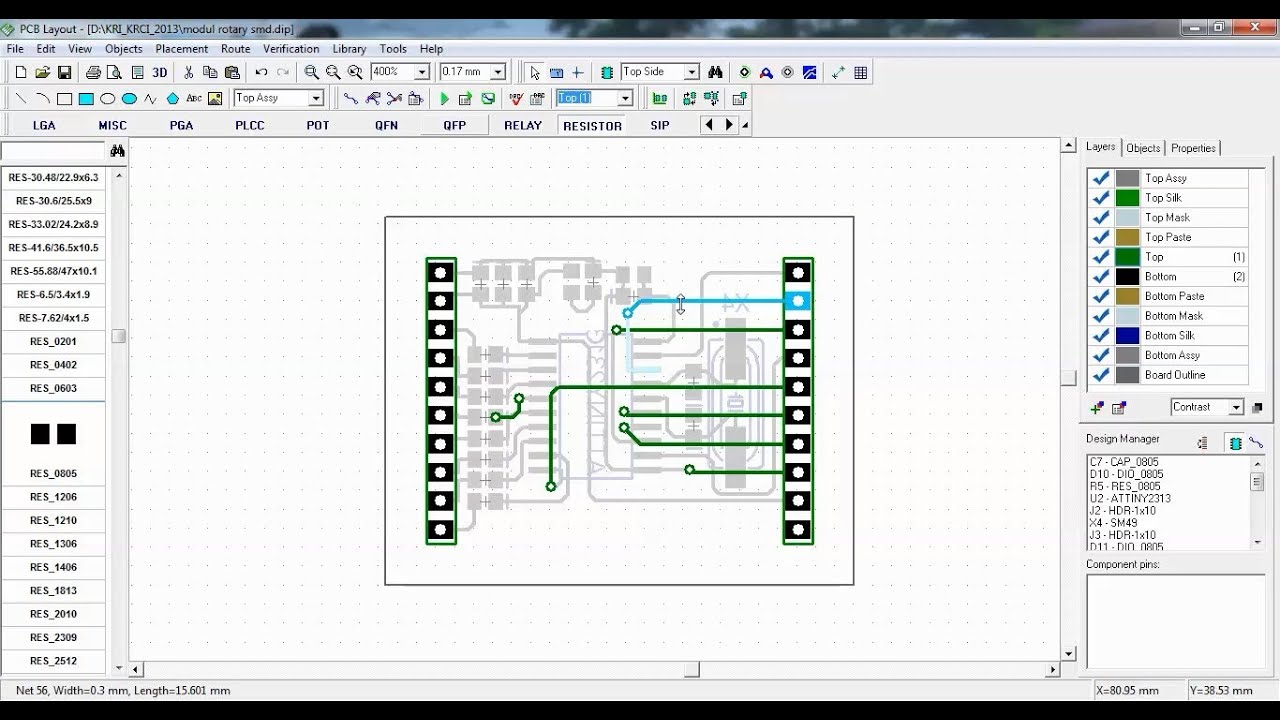

The resulting Gerber files were then converted to G-Code (.nc files) using a software package called FlatCam.įour. Those operations were also done in DipTrace. Having created the PCB, the next step was to create Gerber files that describe the traces, pads, drills and mills to produce this board. The blue colored arc sections eventually get milled into cooling slots that match up with those on the motor. 1206 size surface mount capacitors are used for C1, C2, and C3. The actual size of the PCB has a diameter of 40 mm.

The user then arranges the parts as needed and defines the other attributes of the PCB such as the size, shape, and the milling operations needed to make them. A single mouse click creates a blank PCB, along with the parts. It was converted to a PCB layout in DipTrace using the features inherent in that program. This version only uses the 3 capacitors, to keep the design simple. Additionally, the PROVer PCB has a Green LED and associated resistor to show when the motor is running and is also a polarity indicator. The PROVer MNS PCB uses capacitors across the motor leads, along with a capacitor on each lead to the frame of the motor.

#Diptrace pcb for cnc pro#

This guide, and the associated files are meant to allow owners of the 3018 Pro to implement this feature via a fun yet challenging project. One of the nice new features provided by the PROVer is that it has a circuit board attached to the top of the motor to control noise coming from the motor getting back into the controller board. SainSmart Genmitsu CNC Router 3018-PRO DIY Kit.Making a Motor Noise Suppression (MNS) PCB for Your Sainsmart 3018 Pro CNC Machineīased off of the works of by Jim Kortge The items you may need

0 kommentar(er)

0 kommentar(er)